Client challenge

EDF Energy is the UK's largest producer of low-carbon electricity. Eight nuclear power plants generate over 75% of the electricity produced by our client in the UK. For the last decade, LRQA has supported EDF Energy in developing and implementing a risk monitor for Sizewell B.

EDF Energy is the UK's largest producer of low-carbon electricity. Eight nuclear power plants generate over 75% of the electricity produced by our client in the UK. For the last decade, LRQA has supported EDF Energy in developing and implementing a risk monitor for Sizewell B.

When our client needed to update this tool, it asked us to help. It was critical that the new solution reflected the latest development platforms designed for modern operating systems. It was also essential that the new solution directly integrated with the model for living Probabilistic Safety Assessment (PSA); the tool would be used by plant personnel responsible for maintenance planning, not just PSA experts.

The interface with the plant and maintenance planning tool was also key. The right solution would minimise the need for manual intervention. Lacking a software package that combined these two areas, our client was finding it increasingly difficult to keep the models aligned.

How we helped

Our client, already benefiting from our RiskSpectrum software as their PSA tool, was interested in the risk monitor tool, RiskSpectrum RiskWatcher. We were able to bring our extensive experience of different plant PSA models to this upgrade project, delivering both consultancy and software support.

-

We advised on the structure of the baseline living PSA model for Sizewell B.

- We advised on how best to use RiskSpectrum’s features to achieve reasonable run-times (2–3 mins), with credible results that were fit for for risk monitor purposes.

-

We helped EDF Energy develop an interface between the plant outage planning tool and the RiskWatcher risk monitor.

Client benefits

Using a risk monitoring tool at Sizewell B that is closely linked to the living, full-scope PSA model offers four main benefits.

-

Being risk-informed in both operations and maintenance planning, helping to manage risk within the boundaries of the technical specifications.

-

Enhanced planning opportunities: RiskWatcher is updated weekly with future planned maintenance activities. This provides a look ahead and enables tasks to be rescheduled if the risk is judged too high.

- Greater assessment: RiskWatcher is being used ‘on-line' by operators to assess the impact of emergent work and help prioritise return to service or further planned plant release.

-

Further commercial and safety improvements by making use of RiskWatcher data.

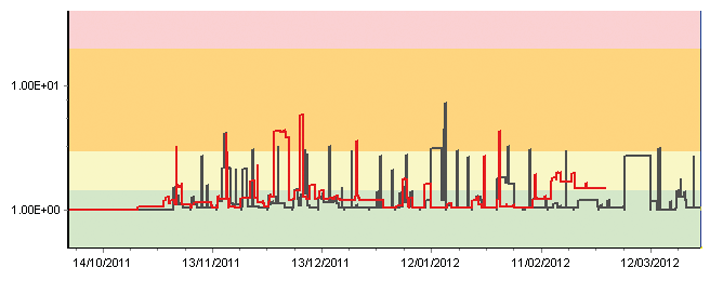

Figure 1: RiskSpectrum RiskWatcher can compare risk exposure based on different maintenance regimes

Figure 1: RiskSpectrum RiskWatcher can compare risk exposure based on different maintenance regimes

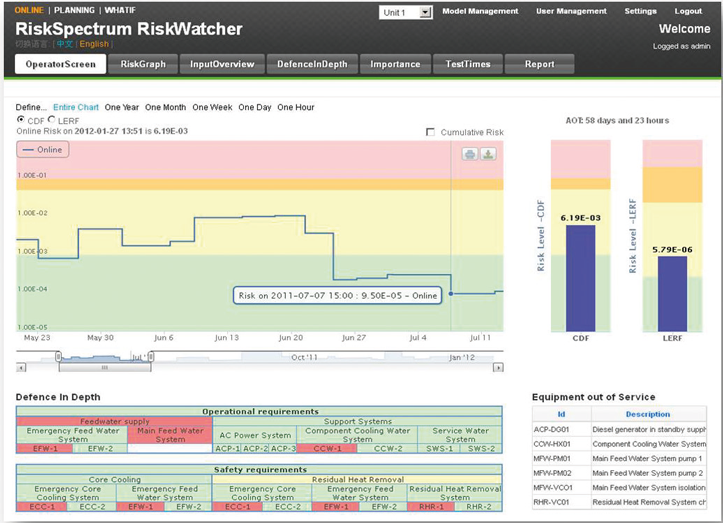

Figure 2: The RiskSpectrum RiskWatcher Interface gives a complete picture of the plant’s risk exposure based on current operating status.