Client challenge

Continental Disc Corporation (CDC) is a leading manufacturer of rupture disc devices. They provide services to over 40 process industries worldwide including chemical, petrochemical, petroleum refining, pharmaceutical, food and beverage, aerospace, industrial gases, and transportation.

Prior to becoming an LRQA client, CDC used a local agency to inspect their reverse acting rupture discs (bursting discs). These are state of the art products utilizing a highly accurate manufacturing method to achieve and control a burst pressure within close tolerances. The inspection agency provided on-site services on a set day each week without flexibility for contingencies like delays and scheduling issues.

This rigid format was not only difficult from a scheduling standpoint, but when an inspection had to be delayed, CDC still incurred charges.. The client wanted greater flexibility and reduced cost, and from a provider with wide knowledge of international codes and standards.

How we helped

Our team met with CDC’s quality team to discuss the issues they were having and to assess their unique inspection requirements. After this assessment, LRQA presented CDC with an innovative remote inspection solution to augment their on-site inspection process.

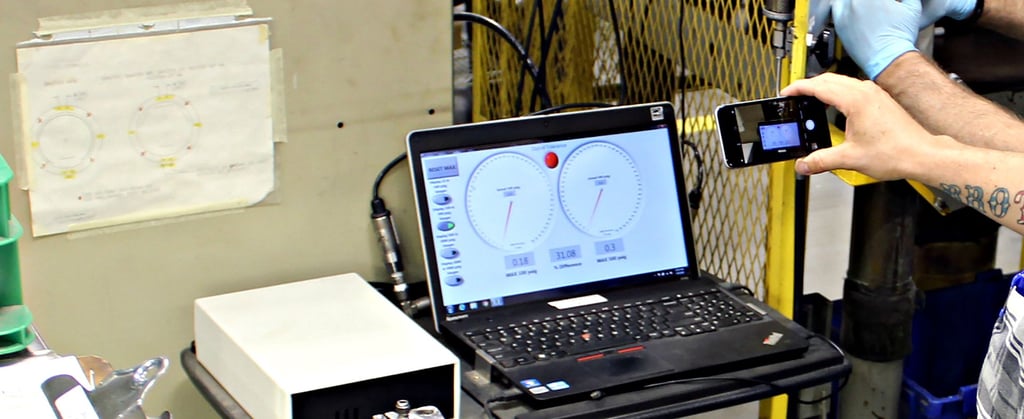

Remote inspection is the live-streaming of audio and video by a trained member of either a company’s quality team or by an LRQA surveyor. This enables stakeholders in remote locations to watch an inspection in real-time and also review the recording at a later date.

For CDC, testing of the burst discs are conducted at the client’s location in Missouri and streamed live to an LRQA surveyor at our Houston technical facility. This allows LRQA to maintain its high standards for quality, while providing a flexible solution for CDC.

The impact

Using LRQA's remote inspection capabilities has improved CDC’s inspection process, giving them a process that is less costly and adaptable to their needs. CDC now has the flexibility to schedule inspection services around their production schedule, getting their products to market on time and in compliance. With remote inspection, the client has:

- More flexible service delivery

- Improved visibility and traceability

- Reduced costs associated with time and travel

- Access to the knowledge and expertise of the LRQA team worldwide

“The team at LRQA has been great to work with and they were very helpful working out the technical issues we were having in the initial development phases," Darren Heyka, Quality Manager, Continental Disc Corporation. "The remote inspection program is working very well for Continental Disc allowing us to be more flexible in our production scheduling and providing our customers with a high quality product when they need it.”

"The remote inspection program is working very well for Continental Disc allowing us to be more flexible."

Powerful results

Since moving to LRQA's remote inspection services, CDC’s inspection costs have been reduced by more than 50%.

KNOW MORE. RISK LESS.

Key services and solutions

Here are links to some of the services and solutions that came together to deliver the project.