Historically, responsible sourcing programs focused on NGO disclosures to prevent reputational risks. Now, with the US CBP actively enforcing forced labor laws, programs face direct financial penalties.

In the past, the principal worry of responsible sourcing program leaders has been the disclosure of problematic factory behavior by NGOs. Such disclosures could lead to consumer action against the brand and thus negative investor reactions. These risks have typically been recognized as reputational risks. With the United States Customs and Border Protection (CBP) now increasingly enforcing forced labor laws through the detention of shipments, responsible sourcing programs are facing direct, immediate and tangible financial penalties.

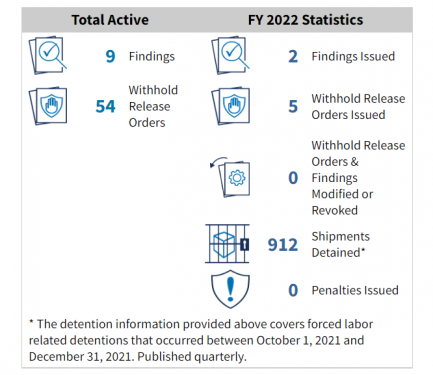

The rise of Withhold Release Orders

Over the past two years, CBP has issued numerous Withhold Release Orders (WROs). In Q4 2021 over 900 shipments were detained. These WROs have impacted numerous industries, products, and companies across the globe.

Figure 1: CBP forced labor statistics and enforcement actions

Source: US Customers and Border Protection website

Source: US Customers and Border Protection website

WROs are issued when there is “reasonable evidence of forced labor” in the production or manufacturing of goods being imported to the US. A WRO can stop shipments from entering the US and detain them at the border until importers can prove that the products being shipped were not produced with forced labor. If CBP issues a “finding” that forced labor was involved, then the product will be seized.

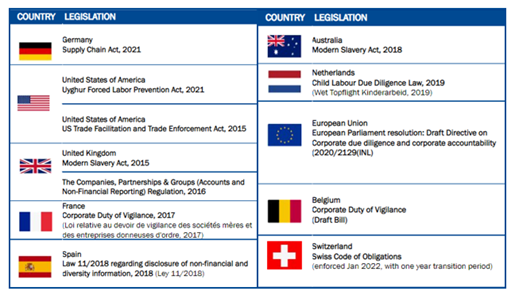

Many countries have passed laws over the years relating to forced labor, but CBP enforcement using WROs has changed the calculus. Similar instruments are being evaluated by the European Union. As a result there appears to be emerging a new standard of supply chain ESG due diligence – and some very difficult questions around the adequacy of current social responsibility programs.

Figure 2. Examples of regulation with modern slavery, forced labor and supply chain implications

The expectations for responsible business have escalated

The degree to which companies know their suppliers (KYS) using traditional compliance programs appears insufficient for this new, more stringent regulatory landscape.

First, these new regulations apply to all aspects of the product, including raw materials, manufacturing, packaging, logistics, and transportation. But traditionally, most social compliance programs have very limited visibility upstream to 2nd and 3rd tier suppliers and beyond. As a result, companies are challenged to expand the breadth and depth of their compliance programs.

Second, these new regulations place the burden of proof on the company. But many companies have opted to utilize supplier Self-Assessment Questionnaires (SAQ) or mutual recognition audits for social compliance. The unintended byproduct of these tools may be lower quality, less transparent, less rigorous and less trustworthy documentation. As a result, companies are challenged to re-focus on quality interventions that guarantee the requisite burden of proof to align with CBP (and other regulator) requirements.

These challenges mean that companies are now compelled to implement risk-based. segmented responsible sourcing program designs that are focused on visibility and transparency, (especially for the most material suppliers), and a more aggressive approach to understanding and managing suppliers. The need for more robust responsible sourcing programs is clear!

Building a fit-for-purpose responsible sourcing due diligence program

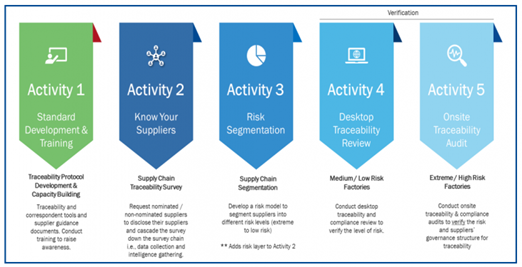

With LRQA’s (formerly ELEVATE Ltd) end-to-end ESG ecosystem, businesses can build the necessary data and management systems to transition to this new standard in due diligence. Below is a sample of a typical LRQA (formerly ELEVATE Ltd) traceability solution which leverages our industry-leading Advisory, Analytics and Assessment services.

Figure 3: Example of a traceability solution that leverages both systems and on-the-ground expertise

Our approach starts with supporting companies to understand the problem and develop appropriate, purpose-fit solutions and systems that go much deeper into supply chains and enable true KYS.

Modern supply chains are too large to apply the same level of scrutiny and engagement to every supplier. In addition, risks can be highly concentrated or nuanced depending on the country and product / commodity. And companies may have a different level of risk appetite. It’s for this reason that our next step is to segment and prioritize suppliers using a systematic, data-driven and risk-based logic.

The appropriate verification method is then applied to each supplier. Lower-risk suppliers may require a lighter touch desktop traceability review. In contrast, higher-risk suppliers may justify a more intensive onsite traceability and compliance audit or review.

Such an approach enables companies to meet the higher standards. Additional programs may then further strengthen responsible sourcing functions to prepare companies to proactively identify, prevent, respond to and remediate supply chain ESG risks. We deliver these solutions via our EiQ technology.

If you are interested in learning more about the new standard in due diligence, the implications to your social responsibility program or in our traceability solutions, please contact us.