Client challenge

Hydratight’s bolted joint solutions serve pressure equipment globally. They support leak-free start-ups and operations across sectors and have a world-class reputation. Hydratight champions the highest standards in joint integrity management, which includes training bolting technicians. Today, the company’s training programme spans 19 centres globally, with 45 instructors.

Hydratight’s bolted joint solutions serve pressure equipment globally. They support leak-free start-ups and operations across sectors and have a world-class reputation. Hydratight champions the highest standards in joint integrity management, which includes training bolting technicians. Today, the company’s training programme spans 19 centres globally, with 45 instructors.

As industry leaders, Hydratight saw an update to an international standard as an opportunity to reinforce customer and stakeholder confidence. This was an appendix introduced by the American Society of Mechanical Engineers (ASME) to its 2010 PCC-1 ‘Guidelines for Pressure Boundary Bolted Flange Joint Assembly’. For the first time, a standard addressed the training of bolted joint personnel, enabling Hydratight to get its training programme certified. The challenge was that no third-party specialist had ever attempted such a sweeping review in this area.

How we helped

We brought three key areas of expertise to this certification project.

We brought three key areas of expertise to this certification project.

-

An existing understanding of Hydratight’s business, based on providing annual reviews for the company’s ISO 9001, ISO 14001 and OHSAS 18001 accreditations.

-

In-depth ASME Code knowledge, delivering Authorised Inspection Agency services for more than 40 years globally.*

-

Valuable bolted joint assembly experience held by several of our ASME Authorised Inspectors.

Over several months, we worked alongside Hydratight to assess its full operational procedures, training and qualifications programmes. The audit results demonstrated that Hydratight’s policies and procedures met the guidelines set out in ASME PCC-1-2013 Appendix A. We are now helping Hydratight to continually enhance its training by providing ongoing, independent reviews and learning.

*All ASME Authorised Inspection Agency activities are performed under the accreditation held by LRQA Verification Limited.

Presenting the ASME PCC-1-2013 Appendix A Qualifying Organisation certificate

(L to R): Andrew Pitts, LRE ASME Team Leader; Jason Barnard, Hydratight Technical Competency Leader, and Sasha Gallagher, LRE Team Leader - UK South.

The impact

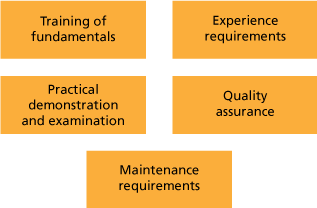

Each organisation seeking certification to PCC-1-2013 Appendix A must have a training program that contains five main components:

Client feedback

“Because of LRQA’s extensive industry experience with the ASME code, combined with its reputation as an independent, safety-driven organization, we can now add another layer of confidence for our customers and stakeholders, continuing our role as an innovator in the industry.”

Wayne Dennis

Director of Growth & Innovation, Hydratight