To reduce the real (and rising) business risks that ESG issues in companies’ supply chains pose, investors need to apply more sophisticated due diligence approaches, including going upstream and on site.

To reduce the real (and rising) business risks that ESG issues in companies’ supply chains pose, investors need to apply more sophisticated due diligence approaches, including going upstream and on site. The financial performance of an investor’s portfolio is inextricably linked to the management practices of the companies within it, and ESG practices are no exception. Operational challenges, regulatory non-compliances and drops in popularity with customers resulting from poor ESG practices all have the potential to affect the performance of an investment. Because of this, investors will benefit from a more hands-on approach to ESG due diligence both at the pre and post investment stages.

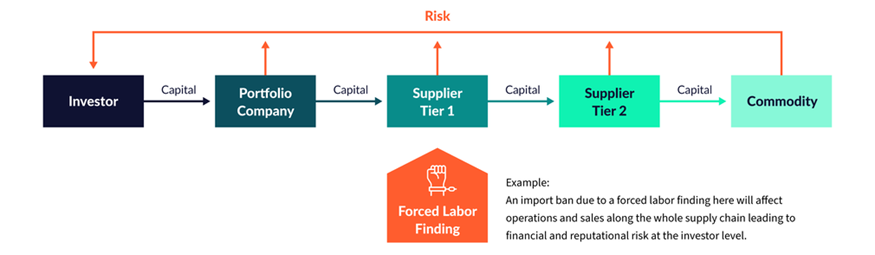

Investors with portfolios with wide-reaching and global supply chains, particularly, have much to gain from supporting their portfolio companies to manage ESG not just within their own operations, but throughout their supply chains. Regulatory developments in labour and human rights due diligence mean that companies could be exposed to debilitating fines or import bans if they do not properly manage these risks in their supply chains and, as a result, investors are in turn exposed to financial and reputational risks.

Our recent supply chain ESG due diligence work with a large development bank highlights the importance of approaching risk in a way most investors fail to do so: proactively. Investors are increasingly turning to third-party providers to improve their risk management, and for good reason. In this case study, our assessment of a manufacturer supplying an energy project, into which the bank was considering an investment, uncovered critical risks and recommended remediation efforts to ensure proper risk mitigation in the future.

Investigation exposes labour, health and safety risks

Our assessment of the manufacturer included a site assessment of two of its facilities, a Sentinel (media) scan of suppliers and a management diagnostic, including a desktop review of the manufacturer’s policies and procedures, management interviews.

In our site assessment, issues were identified relating to employment contracts, non-employee workers, and health and safety. In one instance, an inappropriate contract clause was found in the contracts of non-employee workers stipulating that those who resign within 10 days of joining would not be paid.

Another issue uncovered during site assessments was discrepancies between dispatched labour and outsourced service contractors, putting the manufacturer at risk of exceeding legal limits for employment of duration for workers.

Other health and safety issues detected during the assessment included health and safety issues such as lack of evacuation plan and emergency exit issues. There were also opportunities for improvement identified for the manufacturer’s supplier management systems. Through these assessments, we were able to provide insightful recommendations to improve site performance, including:

- Formalising its supplier ESG performance evaluation process and ensuring policy alignment

- Raising awareness among suppliers on social responsibility through trainings

- Increasing the number of suppliers covered by the manufacturer’s SAQs and audits to achieve 100% coverage by 2023, and including third-party audits as part of the supplier monitoring process

- Improving carbon performance and emission reduction of its suppliers

Lessons learned

Manufacturers in global supply chains must navigate complex logistics, comply with various regulations, and manage relationships with suppliers and customers around the world. This complexity can increase operational challenges and costs. In order to manage these challenges, manufacturers often need to adopt sophisticated supply chain management practices, engage in strategic planning, invest in technology, and build strong relationships with their suppliers, customers, and other stakeholders.

With increasing pressure for traceability of upstream suppliers beyond Tier 1 and identifying and managing any potential ESG risks associated with upstream suppliers, proper due diligence measures must be put in place. The results of risk assessments directly impact investors, who bear the financial risk associated with a portfolio company’s operations. If the company or project performs well, investors can benefit both financially and reputationally. However, if the company or project struggles – due to supply chain disruptions, poor management, or other issues – the value of an investment could decline.