Supply chain risk mapping can equip companies for maintaining the stability and robustness of their practices, even when faced with volatility in sourcing markets.

Even the most resilient responsible sourcing programs will face unforeseen risks that will threaten the risk control mechanisms they have put in place. Supply chain risk mapping can equip companies for maintaining the stability and robustness of their practices, even when faced with volatility in sourcing markets.

Pandemics, political instability, rising regulations, production disruptions and extreme climate events will continue to evolve and take shape, testing supply chains financially and operationally: increasing the risk of ESG violations. Supply chain risk mapping is a process used to lessen risk unpredictability and their repercussions on a supply chain’s operations, by gaining greater visibility over the end-to-end components of a supply chain and organising them by risk level. With greater visibility and effective prioritisation through risk mapping, companies can be better equipped to predict and manage future risk.

Understanding the basics

Risk mapping is the process companies use to illustrate their entire supply chain operations, identifying and mapping information on each of the suppliers and individuals involved. Risk mapping is vital to achieving supply chain due diligence to reduce risks, meet regulatory requirements, and increase transparency for key stakeholders.

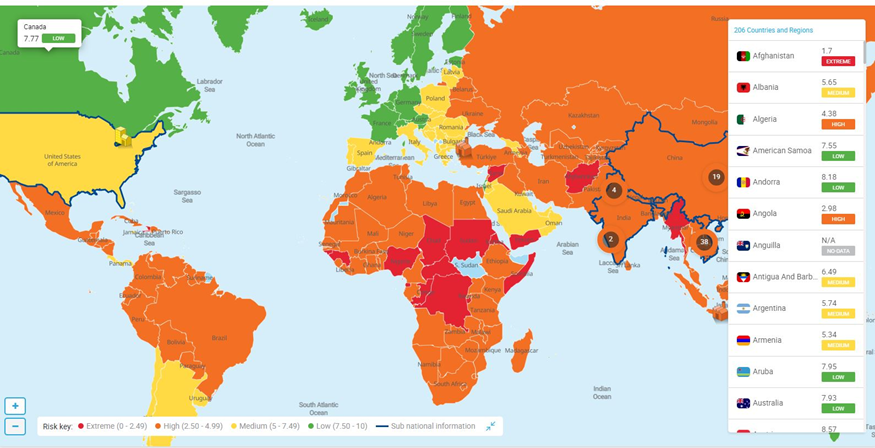

Our supply chain due diligence assurance platform EiQ leverages audit data and civil society data to conduct risk mapping for brands and retailers, producing risk heat maps based on supply chain program information, as shown above.

Limited visibility can lead to damaging missteps

We consistently see gaps in frameworks from even the most well-known companies, whose oversights of human rights violations within their supply chain have led to severe reputational damage.

Media reports have increasingly exposed companies for instances of forced labour, child labour, and inhumane treatment – all of which were the result in part of lack of visibility over what may have been viewed as “distant” operations. Supply chain risk mapping, under the right expertise and using quality data sources, seeks to resolve and reduce these potential threats from violations.

Getting started

Given the complexity of most supply chain operations, the process for risk mapping an entire program can be a challenge. To get started, we recommend building the foundation with these simple steps:

- Data Collection: Data collection will be one of the most valuable steps in the risk mapping process, as it requires a holistic and quality data set. Without accurate and quality data, transparent risk mapping will not be possible. The data process includes:

- Defining the specific ESG risk factors that are most relevant to your industry and organisation

- Gathering data on suppliers’ ESG practices and analysing historical ESG incidents

- Monitoring ongoing ESG performance indicators

- Risk Prioritisation: ESG risks should then be prioritised based on their significance and potential impact. For example, a supplier from an essential sourcing site that is located in a high-risk region and has a history of critical audit violations might be considered a higher priority.

- Visualisation: The results of the ESG risk assessment are typically visualised on a supply chain ESG risk map. This map can take various forms, such as a heat map, a dashboard, or a matrix. Visualisation helps supply chain professionals understand where ESG risks are concentrated and their potential severity.

Example of a segmentation outcome in our EiQ platform based on supplier risk exposure versus risk management metrics

After risk mapping, organisations can develop strategies and action plans to mitigate and manage the identified high-priority areas. These plans often involve corrective action plans to improve site performance, setting targets, and potentially planning more frequent audits for high-risk sites.

Supply chain ESG risk mapping is an ongoing process. Companies must continuously monitor ESG risks, review progress, and report on their efforts. The more insight companies can have into the operations from raw sourcing to selling in-store, the better-equipped they can be to prevent any disruptions to these operations.