Client challenge

Enerpac produces heavy lifting equipment at their Hengelo, Netherlands location. Due to the safety critical nature and significant investment of the equipment, Enerpac's clients appreciate their mandatory third-party endorsed certificates and approvals of their products. LRQA has been Enerpac's third-party inspection provider for nearly 30 years.

Enerpac's customers are now looking for more assurance in their supply chains taking advantage of technology to make the process convenient for them.

"Technological developments (Internet of Things) ensure that people expect more and more from us, their supplier," said Peter Brueker, Enerpac sales coordinator. "This requires us to be more innovative with our internal processes, for instance, at our production and quality department. One of the aspects of this is the inspections."

This means technology-enabled inspections accessible to the client, no matter where they may be, or what timezone in the world they are in. Logistically, this is a challenge for any manufacturer, and for Enerpac it was no different.

The difference for Enerpac? Its close working relationship with LR.

How we helped

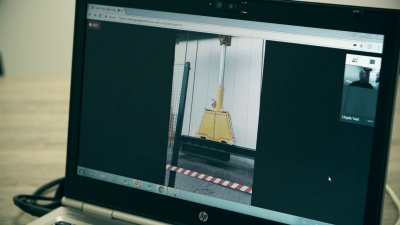

LRQA offered Enerpac its new remote inspection service. Instead of repeat on-site visits, this allows Enerpac quality personnel to livestream factory acceptance testing (FAT) to an LRQA surveyor to witness and approve using a smartphone app.

Safety is important not only for the equipment, but for the remote inspection process. Enerpac reviewed its own internal processes and test protocols and adjusted them with help from LR. Also Enerpac’s quality staff use a tripod to hold the camera for the livestream, staying connected through a Bluetooth headset to keep their hands free and prevent them from being distracted.

Compliance is tracked through remote inspection certificates as well as tamper-proof LRQA approval seals on the equipment.

The quality of (remote) inspection is at the same level but the availability of evidence has increased. It is truly a win-win situation, both for us and for our customer.

The impact

Enerpac now uses remote inspection as a selling point for clients.

Clients can witness the FAT themselves through the livestream, or they can view them on-demand. The flexibility of remote inspection also means faster service, and a reduction in time and cost savings of LRQA surveyor site visits.

Clients can witness the FAT themselves through the livestream, or they can view them on-demand. The flexibility of remote inspection also means faster service, and a reduction in time and cost savings of LRQA surveyor site visits.

“Remote inspections allow us to satisfy our customers faster," said Mart Hinnen, Enerpac's general manager. "We are therefore able to deal with the customer's wishes/demands more easily while the level of convenience has increased. The quality of inspection is at the same level as a personal inspection but the availability of evidence has increased. Our customers can now choose whether to watch live or see the evidence of the test later when it suits them. It is truly a win-win situation, both for us and for our customer."

LRQA tailors its remote inspection service to each client's individual needs. If you'd like to learn more, please get in touch.

Key services and solutions

Here are links to some of the services and solutions that came together to deliver the project.