Organisations in high-risk sectors have long found some of their greatest learning and performance improvements emerge from focusing on High Potential Incidents (‘HiPos’): serious near-miss events that could have resulted in a fatality or life-changing injuries.

Every organisation experiences these events and they occur at a greater frequency than we’re probably aware of. What’s more, studies of major accidents have found that they are frequently preceded by precursor events. That’s why focusing on the potential of incidents, rather than the actual outcome, provides a deeper learning opportunity and is a good indicator of an organisation’s inherent risk profile.

So what can we learn from an analytical approach to HiPos, and what are the considerations when applying a HiPo strategy?

Defining HiPos

One reason HiPos are not more commonly adopted is that, unlike lagging indicators, no standardised definition exists. The most common definition is an event that, if one factor had been different, might easily have resulted in a fatality. If a surface had been icy, for example, a slip or trip might have had more serious consequences. Some organisations apply a lower threshold and include potential incidents that could have resulted in life-changing injuries.

Identifying them

Organisations wishing to learn from their HiPos need to establish a method to identify them. Given that most HiPos do not result in the harm, a good starting point is exploring the near miss, observations and safety reporting systems to actively seek out the incidents that, in slightly differently circumstances, could have resulted in very different outcomes.

Various methodologies exist to identify the potential harm of an incident. Some involve informal judgement, while others use formalised methodologies including a risk matrix, severity scales, decision trees and algorithms.

Investigating them

Not all incidents are equal, and some have greater potential for learning and improvement. In a world of limited resources, it’s necessary to prioritise incidents in order that investigations are proportionate to the potential, not solely the actual outcome. A risk-based approach to investigations, categorising them by potential consequences, is the most common method to ensure resources are proportionately applied.

While many HiPos will be identified from incidents that workers experience within their job, they will also arise within asset failures, often lying dormant until identified through inspections or failures. Establishing a strong link between the inspection regimes of safety-critical assets and processes, and the incident reporting system is therefore essential.

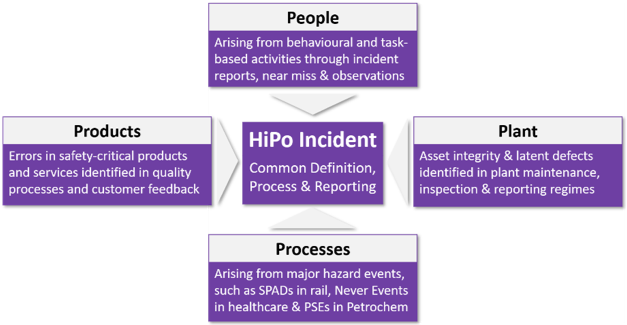

High-risk organisations also experience HiPos within their operational activities, as do providers of safety-critical services and products. Establishing a common reporting and methodology for all HiPo events can be advantageous and provide invaluable metric for organisational-wide management of risk.

Cultural enablers

The importance of organisational culture is often underplayed in HiPos strategies. Given that many high-risk events will only be apparent to those performing the work, HiPos programmes rely upon the participation of frontline personnel to share their experiences.

This requires a system that encourages open and accurate reporting without fear of reprisals. Training and communication help establish the necessary trust, providing a forum to discuss concerns around reporting. Education will also help address a common factor with HiPos: risk normalisation. This describes the process where we gradually become accustomed to high risk situations and no longer recognise the dangers.

Those new to HiPo reporting would be wise to consider how the information HiPos reveal will be received by their leadership teams and prepare the ground. This is important, because how managers respond to the mistakes, lapses and deviations that investigations reveal will shape the culture and determine workers’ future engagement. These challenges are worth addressing, however, because HiPos help leaders maintain chronic unease and appreciate the fallibility of their current controls.

Precursors

Organisations that focus on HiPos often find that most serious incidents involve a small number of high-risk activities. In-depth studies of each of these activities will often reveal a Pareto distribution, whereby 4-5 precursors appear in many HiPos.

There are various definitions of precursors. My preference is ‘a high-risk situation in which controls are either absent, ineffective or not complied with, and would result in a serious or fatal injury if allowed to continue.’ Precursor analysis also enables more evidential interventions to be taken where outcomes can be measured. This is particularly important when seeking to make changes in organisational factors such as scheduling and technology.

Fixing them

The term ‘one barrier from a catastrophe’ is often used in connection with HiPos and succinctly describes incidents that could have been much worse but for one factor. This one factor is often luck, such as an individual’s actions or location, an item of equipment, the time of day or even the weather.

Investigations into HiPos often identify the fallibility of controls for high risks, many of which are reliant on controls at the bottom of the hierarchy, or single barriers that represent a single point of failure. Corrective action provides the opportunity to address this fallibility by establishing more effective controls.

Summary

Focusing on HiPos requires organisations to change their focus from a reactive view of responding to incidents, towards a proactive examination of the conditions that lead to major accidents. It also requires organisations to reassess what they view as success and focus on the adequacy of their controls.

Organisations that can navigate these challenges will however ensure that their efforts are focused on reducing their significant risks and that must be primary obligation of every OHS practitioner.

Faster, more accurate analysis of HiPos with LRQA SafetyScanner

LRQA Aurora, our digital innovation practice, has worked closely with LRQA clients to develop the LRQA SafetyScanner, an AI-driven analytics solution that provides much deeper and faster insight into the conditions that give rise to HiPos.

SafetyScanner has helped clients quickly and accurately identify the combinations of circumstances that lead to HiPos, enabling them to implement effective strategies for reducing injury and loss. One major food service retailer, for example, has significantly reduced customer injuries and insurance claims by using SafetyScanner to uncover and address previously-hidden areas of risk.

If you’d like to know more about how we can help you to identify, analyse and learn from HiPos, please do get in touch.